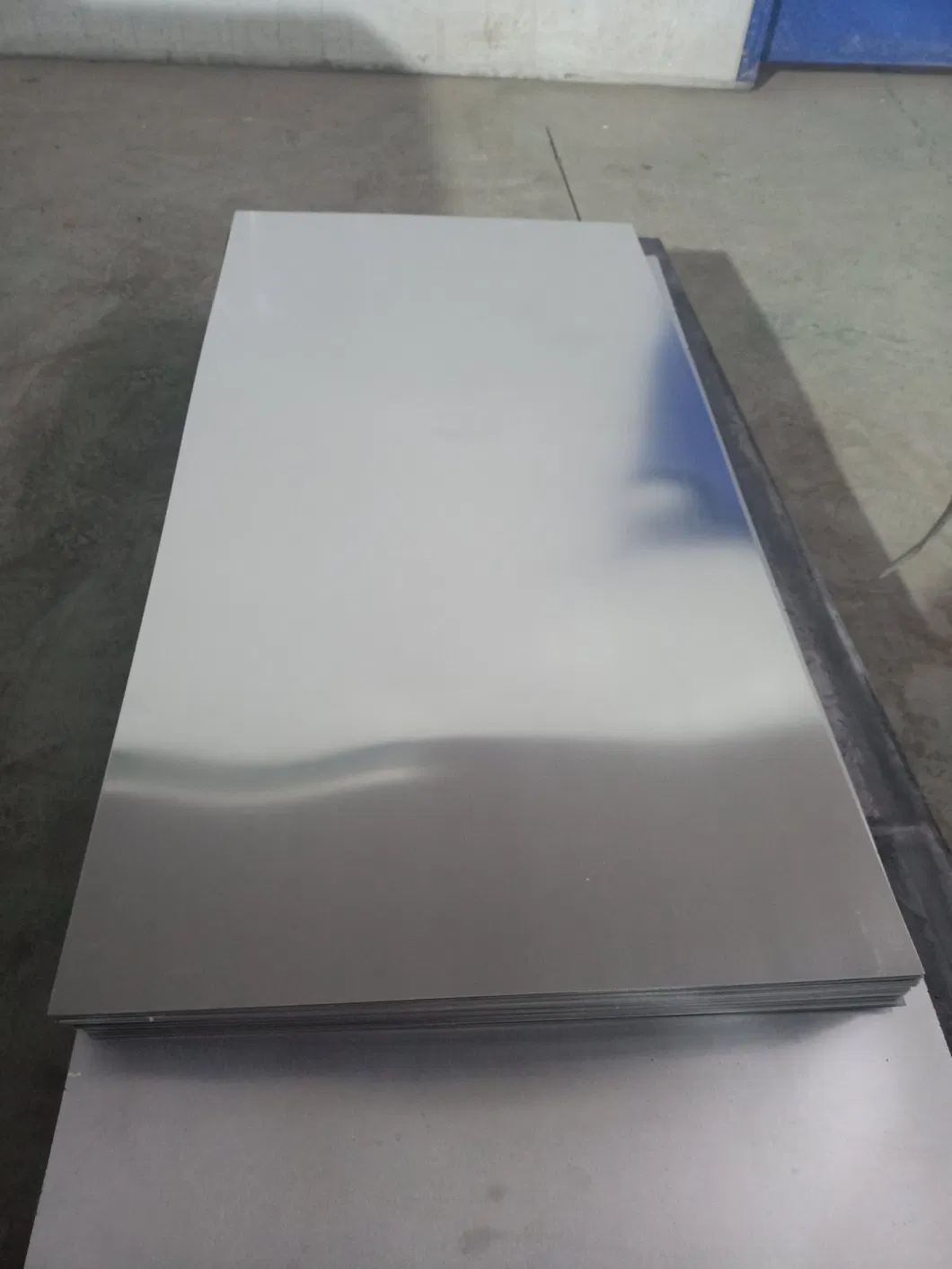

Thinner Pure Molybdenum Sheet, Molybdenum Foil, Polished Molybdenum Plate(Disc), Molybdenum Round Sheet Molybdenum Copper Alloy Mocu Molybdenum 0.3mm and 0.5mm

Pure Molybdenum sheet/Plate, Molybdenum Lanthanum Mola Sheet and Molybdenum lanthanum sheet plateMolybdenum sheet/plate/

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | Mo sheet |

| Surface | Polished, Annealed |

| Condition | Hot Rolled, Cold Rolled |

| Density | 10.2g/cm3 |

| Transport Package | Wooden Box(Foam Board Around The Inner Wooden Box) |

| Specification | thickness0.05mm, 0.08mm, 0.1mm, 0.2mm, 0.3mm |

| Trademark | JiangChi |

| Origin | China |

| HS Code | 8102950000 |

| Production Capacity | 200t/Year |

Product Description

Pure Molybdenum sheet/Plate, Molybdenum Lanthanum Mola Sheet and Molybdenum lanthanum sheet plateMolybdenum sheet/plate/foil/stripspecification:1) Purity≥99.95%2) Density:10.2g/cm33) Size: Thickness 0.05-50.0mm Width 20-800mm Length 100-3000mm or as your need4) Grade:Mo1/MoLa/TZM5) Processing:cold rolled, Stress relief annealing, Hot rolled6) Surface: polished, washed, ground, grinding.Molybdenum sheet/plate/foil/strip-Mo1/MoLa/TZM99.95% Molybdenum Sheet, Molybdenum Strip 0.3mm 0.5mm Thickness1. Purity: Mo>= 99.95%2. Standard: GB/T 4182 or ASTM3. Property specification 1) high melting point, high strength, 2) smooth and clean surface, 3) good conductions, small linear expansion coefficient and good heat-resistance.

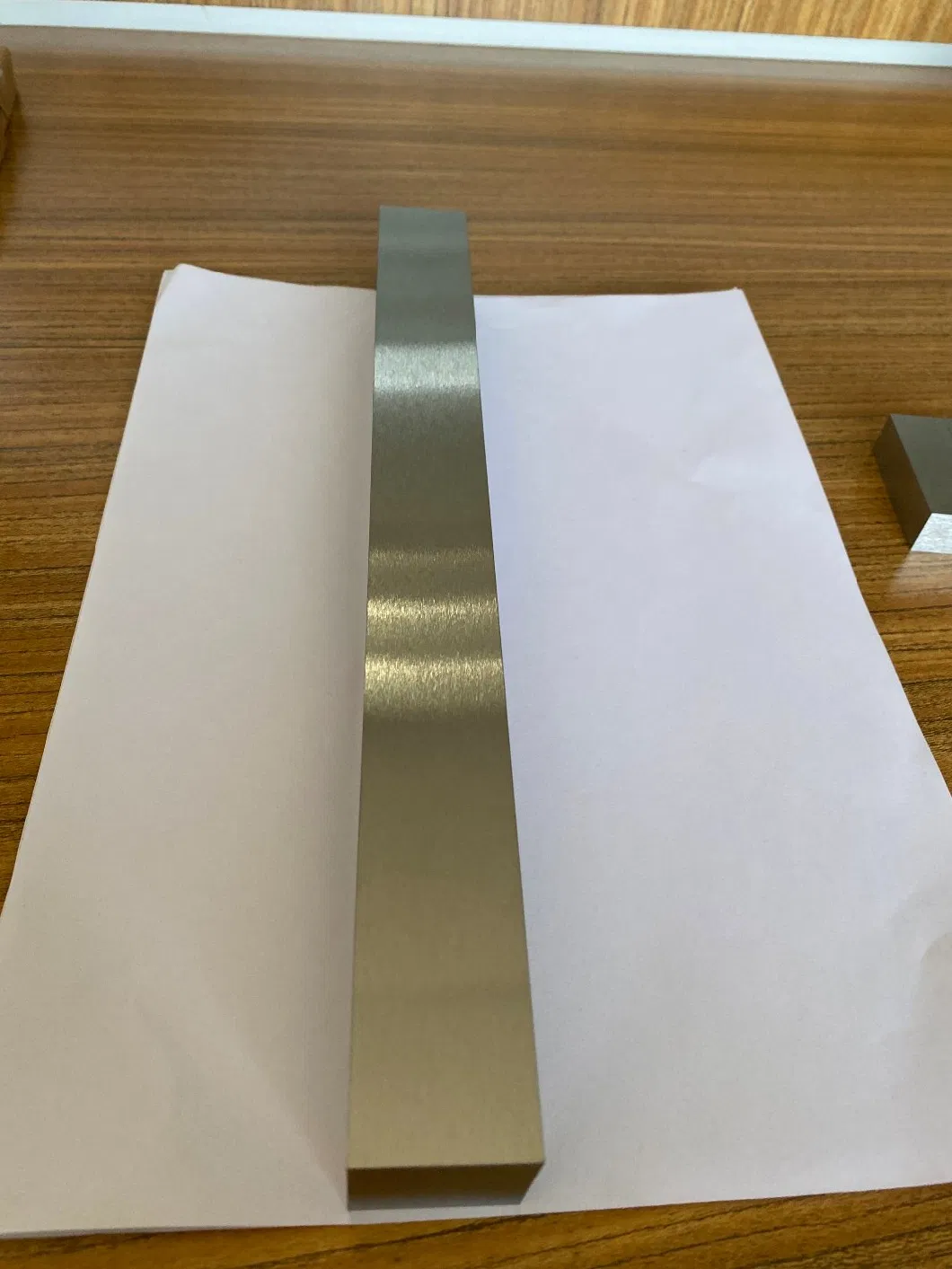

Molybdenum copper alloy forged rods Molybdenum contents 50%-85%Mo-Cu composites has lower density, its thermal expansion coefficient and thermal conductivity can be adjusted to match many different materials.MoCu alloy physical Properties of Major Products

| Material | Wt%MolybdenumContent | Wt%Copper Content | g/Density at 20ºC | W/M.KThermal conductivity at 25ºC | (/k)Coefficient of thermal expansion at 20ºC |

| Mo85Cu15 | 851 | Balance | 10 | 160-180 | 6.8 |

| Mo80Cu20 | 801 | Balance | 9.9 | 170-190 | 7.7 |

| Mo70Cu30 | 701 | Balance | 9.8 | 180-200 | 9.1 |

| Mo60Cu40 | 601 | Balance | 9.66 | 210-250 | 10.3 |

| Mo50Cu50 | 500.2 | Balance | 9.54 | 230-270 | 11.5 |

Features of Molybdenum copper alloy:1)Large sized sheets available ( we can supply as the customers' need)2)More easily to be stamped into components than CMC3)Very strong interface bonding which can repeatedly resist 850ºC heat shock4)Higher thermal conductivity and lower cost

Molybdenum copper alloy application:molybdenum copper used in spaceflight fields.Molybdenum copper alloy has more excellent performances, so can be used as high temperature part of rockets and missiles. This alloy has high thermal conductivity, thermal expansion, high melting point, and the good mechanical ability, all of these reasons, which make the molybdenum copper can be used in the spaceflight fields.

Polished Molybdenum Copper Mo80cu20 W80cu20 Alloy Rod and Plate (with high melting point)

Mola and pure molybdenum discs/wafer/washer/sheet

Thinner Molybdenum Sheet Molybdenum Foil Mocu Sheet Tzm Molybdenum Sheet

1. Purity: Mo>= 99.95%2. Standard: GB/T 4182 or ASTM3. Property specification 1) high melting point, high strength, 2) smooth and clean surface, 3) good conductions, small linear expansion coefficient and good heat-resistance

| Thickness(mm) | Width(mm) | Length(mm) | Surface | Rolled condition | |

| MolybdenumPlate | 8.0-16.0 | 10-1000 | 10-1000 | Alkali washed | Hot rolled |

| 3.0-8.0 | 10-1000 | 10-1000 | Hot rolled | ||

| Molybdenum sheet | 1.5-3.0 | 10-1000 | 10-2500 | Acidcleaning | Coled rolled |

| 0.5-1.5 | 10-1000 | 10-2500 | Cold rolled | ||

| 0.2-0.5 | 10-1000 | 10-2500 | Cold rolled |

More information about us:We promise you -- The advantage of us:

1) products quality, with many years of producing experience

2) low price in the market, and factory direct sales.

3) the whole production line from powder to finished products, top and steady quality assured 4) good packing for safe exprot delivery, and fast manufacturing time

5) fast delivery and best after-sale service